Inh. S. Nüssle

Trading&Consulting

Spezialist für Druckluft und Recyclingmaschinen sowie Ersatzteile

Specailist für Heavy Machinery, Weare and Spare Parts

Double click to edit

PROCESSING PLANTS

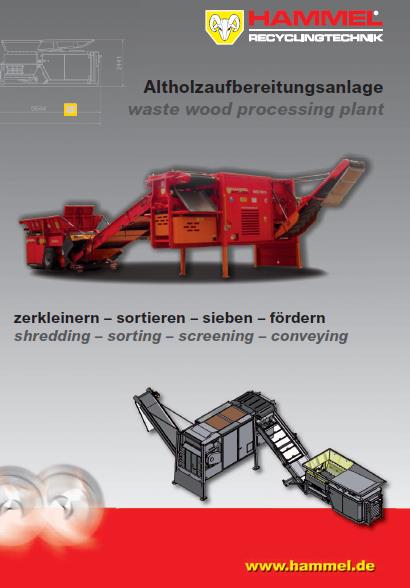

Wood Processing

Applications:

Wood: waste, demolition wood, stem wood, root stems, green waste, railway sleeper, pallets, cable drums.

For the waste wood recycling, the HAMMEL Recyclingtechnik GmbH facilitates processes and techniques to separate contaminants from the waste wood, to yield a reusable product.

The waste wood is processed for the further use with a customized HAMMEL wood recycling plant.

The HAMMEL-primary shredder processes the intake waste wood in a single step to an end product of approx. 300 mm, the discharge conveyor then passes it on to a magnet separator, where iron substances are separated, and is then moved to a vibrating chute. Here, the material is broken up and distributed evenly on the sorting belt in order to facilitate manual sorting of further impurities. The clean material is discharged, depending on size and quality across different belts into the appropriate boxes and is now available for further recycling.

Components:

- Pimary shredder

- Metal separation

- Secondary shredder

- Screening technology

- Sorting lines

- Discharge and conveyor technique

Advantages:

- individual planning

- high performance

- Low energy consumption

- low noise emission

- minimal dust formation

- durable tools

- rugged construction

Waste Processing

Applications:

Waste domestic waste, C&I waste, bulky waste, demolition waste, tires.

Waste of any kind or origin is now a valuable resource. The processing of this raw material into its recyclable materials makes sense economically. The HAMMEL Recyclingtechnik GmbH supports you in this task with its individually planned waste processing plants.

Components:

- Primary shredder

- Metal separation

- Screen technology

- Sorting lines

- Auftrags- und Fördertechnik

Advantages:

- individual planning

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

- rugged construction

Metal Processing

Applications:

Metal: Car bodies, aluminum profiles and bales, engine blocks, white goods, mixed scrap, light metal scrap.

A HAMMEL a metal processing plant offers you the significant advantage: in only one step you can get from compact input material to materially separate end products. Following is a precise separation of magnetic (ferrous) metals and non-magnetic (non-ferrous) material. Because of the system concept with machine components you also have a system with maximum mobility.

Components:

- Primary shredder

- Metal separation

- Secondary shredder

- Screening technology

Advantages:

- individual planning

- high performance

- low energy consumption

- low noise emission

- minimal dust formation

- durable tools

- rugged construction